CUSTOMER FOCUSED SOLUTIONS

We aim to go above and beyond in not just our service but in everything we do: the vehicles, uniforms, materials, logistical planning, operational planning, commitment and training. Our goal is always to go above and beyond to exceed our clients’ expectations.

A SAFETY FIRST APPROACH

At JMAC, we take responsibility for our own safety and for the safety of those on the sites around us. We aim to be the safest company in our industry. We realise that in order to deliver our services safely and efficiently, an efficient and proactive SHEQ Management Process & Systems is fundamental and we continually assess every risk throughout all of our operations, to ensure

appropriate control measures are put in place.

To help achieve our health and safety goals and to fulfil our commitment to regular review, monitoring & improvement, we are also members of a number of relevant associations, and have committed to work with a number of accredited bodies who produce regular audits, including FASET, CHAS Elite, Constructionline Gold, ISO 9001, 14001 and 45001 standards, QSCL, SSIP and members of NASC.

Committed through compliance with these standards and relevant health and safety statutory provisions and best practice, we ensure the protection of employees, agency staff and sub-contractors, contractors and others that may be affected by our activities. Staff training and communications are fundamental and we ensure that all employees undertake appropriate and both internal and external training courses and receive regular and topical toolbox talks.

Logistics

At JMAC Scaffolding we understand that our yard and logistics are a fundamental factor in the success of any scaffolding company.

Being able to transport our materials to and from sites safely requires stringent procedures and management and is just as important to get correct as the scaffolding itself. One of the key success factors is the transport and yard teams co-ordination with the operations team on a daily basis.

At JMAC we have a mixed fleet of HGV’s including Hiab, Hook Loaders, flatbed, dropsides and small vans.

call today for a free quote

Materials

Materials are a fundamental part of any scaffold and at JMAC we understand that only by using the best scaffolding materials we can invest in long term quality and the long-term safety of our clients.

JMAC Scaffolding specialises in traditional tubes and fittings this type of materials which can offer a cost advantage for certain projects, however we can also provide specialist systemised tube and fitting systems using structural transom units, and various system scaffolding products such as Layher, Haki & Plettac Metrix. System Scaffolding can offer an advantage where the type of scaffolding required needs to be erected and dismantled in a short period of time due to time constraints. System Scaffolding also offers a higher load capacity than basic configuration scaffolding built using traditional tubes and fittings to TG20.

Design

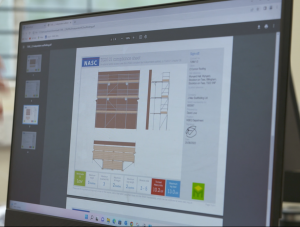

At JMAC Scaffolding we encompass the use of the NASC TG20 E-Guide to provide all clients with either a compliance sheet showing that the scaffolding erected complies with TG20 or a bespoke Scaffolding design with supporting calculations. Designs are identified at tender / surveying stage for each project. JMAC Scaffolding has created relationships with a range of design engineers who support the team on a daily basis.

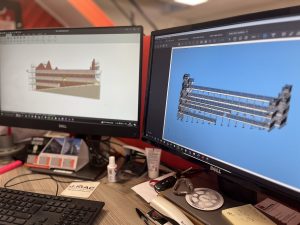

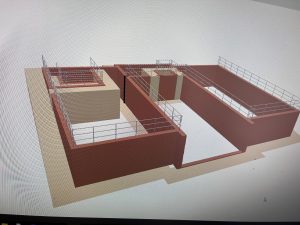

Our 3D dimensional space drawings help JMAC clients to streamline their construction processes.

3D CAD software like Smart Scaffolder is extremely useful for Scaffolding Project Design, because it allows our JMAC engineers and scaffolding management team to quickly generate more efficient designs and a more accurate representation of planned scaffold structures before they are built.

Knowing that everything we produce is fully compliant with regulations, using 3D CAD software also helps us deliver the following to our clients:

- Easier to visualise projects

- Faster turnaround on projects

- More accurate estimates

JMAC Scaffolding ensure full compliance with Work at Height Regulations 2005. Find out more about scaffold requirements on the HSE Website

SMART Scaffolder

JMAC Scaffolding use Smart Scaffolder CADS software, which allows the engineers and scaffolding management team to produce scaffolding designs, quotations, material load lists and test the designs to current TG:20 legislation as per the requirements of the Working at Height Regulations 2005.

All scaffolding projects are planned and co ordinated in line with industry scaffolding guidance notes and technical guidance notes, JMAC’s ability to create 3D Visual Models of a scaffolding structure prior to works starting on site is part of the requirements laid out in the construction design management (CDM) regulations with particular emphasis on the pre planning of construction related works.

Knowing that everything we produce is compliant to industry standards isn’t just for peace of mind, it can realistically prevent disaster and save lives.

Following the rendering and testing of the 3D design, we produce 2D working drawings. These demonstrate the plans and elevations of every aspect of the project, including loading bays, staircases, birdcages and internal walls. By seeing how everything fits together and works in unison, under different circumstances and during a range of scenarios, you benefit from the confidence of knowing that you’re receiving a bespoke system.